New Metal 3D Printer Eliminates Debinding: Print Today -- Parts Tomorrow

The ExOne Company has launched the ExOne Metal Designlab printer and X1F advanced furnace in an exclusive partnership with Rapidia, a Vancouver, Canada-based technology company. Orders are now being accepted, with the system printer and furnace available for delivery in the second quarter.

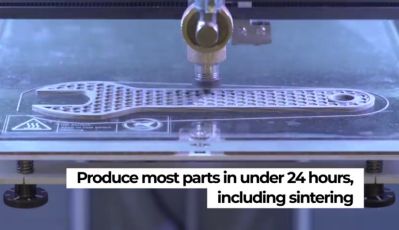

VIDEO: ExOne Metal Designlab by Rapidia

Rapidia's two-step 3D printing technology, developed over several years, and first revealed in 2019, was the first to allow water-bound metal and ceramic parts to go directly from a printer into a furnace without a debinding step. The efficiency is made possible by HydroFuse, an innovative water-based paste containing metal or ceramic powders, which does not require debinding before final sintering.

Two materials are currently offered: 17-4PH and 316L stainless steels -- with other metals and ceramics to follow soon. The ExOne and Rapidia teams are collaborating on system and process enhancements to offer this true "Print Today, Parts Tomorrow™" to the marketplace, with more innovations expected.

The new X1F advanced furnace, with about 10 liters of usable volume, will also be offered across ExOne's binder jet lineup, where it is an ideal complement to the Innovent+ or InnoventPro 3L or 5L printers.

"We are delighted to partner with the visionary Dan Gelbart and the Rapidia technology team to offer the new ExOne Metal Designlab and X1F furnace," said John Hartner, ExOne's CEO. "This technology is a true time-saving innovation that complements ExOne's portfolio. Now, researchers, educators, and industrial designers will be able to bypass days of waiting and produce high-quality parts without the limitations faced by parts that require traditional debinding.

"We set out to develop a simple, environmentally friendly system that creates the toughest, most intricate parts overnight," added Dan Gelbart, Rapidia Founder. "Today, we're excited to leverage ExOne's global marketing and sales team to help customers around the world enjoy the benefits of our revolutionary technology. I also expect a lot of innovation to come from combining the deep technical knowledge of both companies. Now, users can 3Dprint complex parts today without any thickness limitations for solid parts and produce high-strength parts overnight."

A True Print Today, Parts Tomorrow™Innovation

Most other bound metal 3D printing technologies require either three steps (print, debind and sinter) or 3D printing followed by a very slow thermal debinding in the sintering furnace. Either method usually takes3-5 days to produce a final part and comes with limitations on part thickness, so that the part can properly burn off the polymer binders. Often, these systems limit parts to 5-10 mm (0.2"-0.4") thickness, which also limits the final strength and applications for the final part.

By contrast, the HydroFuse paste developed by Rapidia replaces 98% of the binder with water, which evaporates while printing, enabling true "Print Today, Parts Tomorrow™" technology. This technology also removes the limitation on maximum part thickness. The new ExOne Metal Designlab can print 100% solid metal of any thickness, delivering maximum strength parts suitable for a wide variety of demanding pre-production and end-use applications.

The ExOne Metal Designlab will compete directly with other bound metal 3D printing systems, such as the Desktop Metal Studio System 2 and Markforged Metal X.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy